Navigating the Nuances: Essential Tips for Using Filter Plates

Introduction

Hey there! If you're diving into the world of filter plates, you're in for a treat. These handy tools are not just pieces of equipment; they're the backbone of many filtration processes. However, like any other equipment, they come with their own set of quirks and considerations. So, let's explore some key points to keep in mind!

What Are Filter Plates?

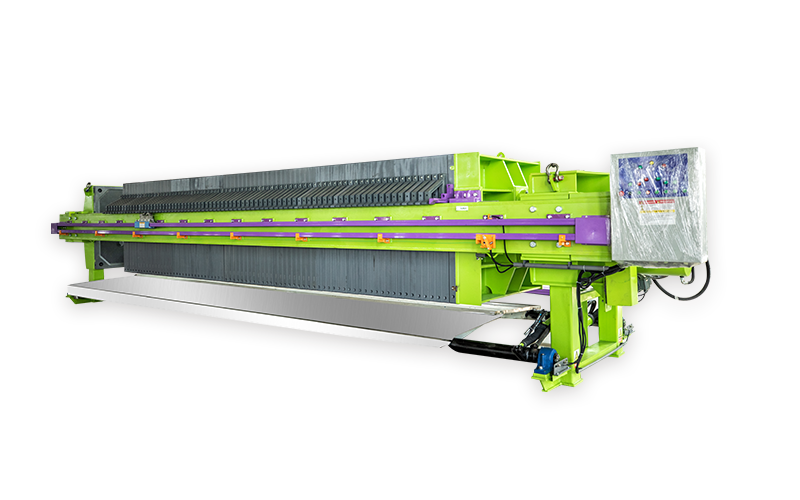

First things first, let's break it down. Filter plates are flat surfaces used in various industrial applications to separate solids from liquids. They can be found in industries ranging from pharmaceuticals to food processing. Think of them as the unsung heroes of cleanliness and efficiency!

Why Pay Attention?

Now, you might be wondering, "Why should I care about these plates?" Well, my friend, improper use can lead to downtime, inefficiencies, and, worst of all, compromised product quality. Yikes! So, let's dive into some critical considerations.

1. Material Matters

When selecting filter plates, always consider the materials. Different applications require different materials—some are better suited for high temperatures, while others excel in corrosive environments. Trust me, you don't want to mix these up!

2. Maintenance is Key

Just like your car needs regular oil changes, filter plates need maintenance too! Regular cleaning and inspection can keep them functioning optimally. A little TLC goes a long way. So, don't skip that maintenance schedule!

3. Be Mindful of Pressure

Pressure and filtration go hand in hand, but be careful! Too much pressure can cause damage to your filter plates. Always adhere to the manufacturer's guidelines—overdoing it can lead to catastrophic failures. Oops!

4. Temperature Tolerance

Temperature can drastically affect filtration efficiency. If your process involves extreme temperatures, ensure your filter plates are rated for it. It's all about finding the right fit for your needs!

5. Check for Wear and Tear

Finally, don't overlook the wear and tear. Regularly inspect your filter plates for any signs of damage—cracks, warping, or other issues can lead to costly errors. Stay proactive!

Conclusion

In a nutshell, using filter plates effectively requires more than just slapping them into place. From choosing the right material to keeping an eye on maintenance, these tips will help you navigate the nuances of filtration processes like a pro! Remember, a little diligence today can save you big headaches tomorrow. Happy filtering!