Products

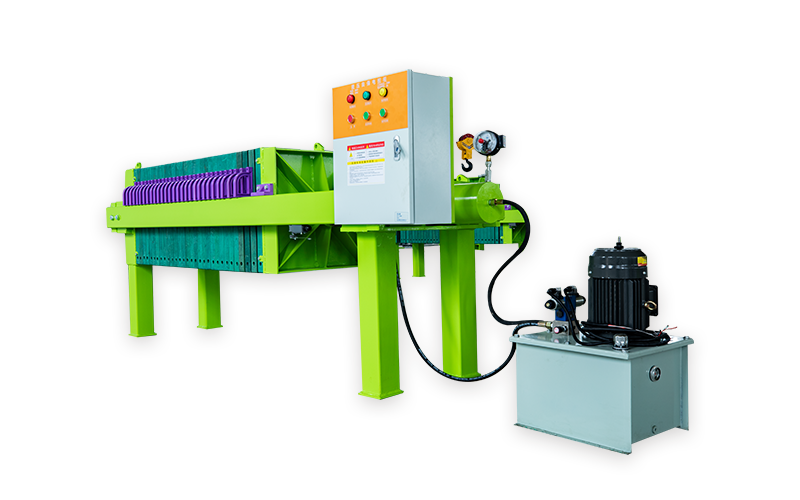

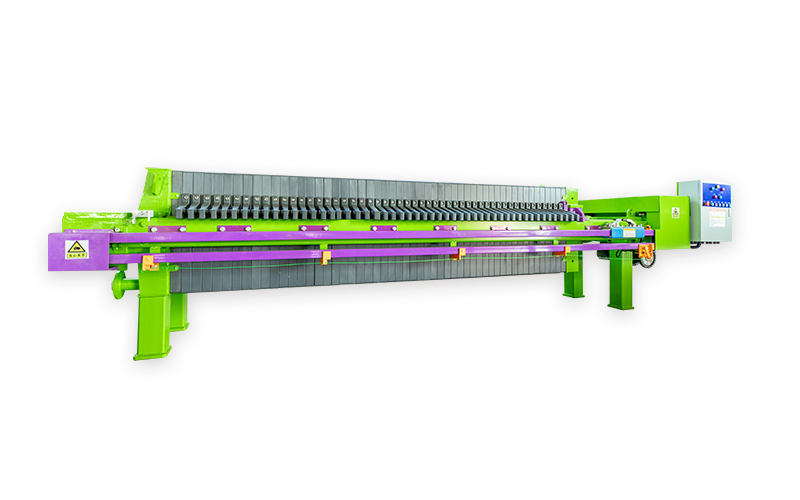

800-type filter press

- Product Description

-

The 800-type filter press is an efficient solid-liquid separation equipment, widely used in chemical, pharmaceutical, food, metallurgy, and other fields. This document will introduce its main features, working principle, application areas, and more.

I. Main Features

1. Large filtration area: The 800-type filter press has a large filtration area, which improves processing efficiency.

2. High degree of automation: The equipment is equipped with an automatic control system, which can realize automatic pressing, automatic pressure holding, automatic loosening, and other functions, making operation convenient.

3. Good filtration effect: Through the filter pressing process, solid-liquid separation can be achieved, resulting in a higher filtrate concentration and lower solid content.

4. Corrosion resistance: The equipment is made of stainless steel, which has good corrosion resistance and is suitable for filtering various corrosive media.

II. Working Principle

The 800-type filter press performs solid-liquid separation based on the principle of filtration. During the filtration process, the material to be treated enters the filter press through the inlet pipe. After passing through the filter cloth, solids remain on the filter cloth to form a filter cake, while the liquid flows out through the filtrate outlet. At the same time, the filter press provides pressure through a pressure pump to complete the filtration process under high pressure.

III. Application Areas

1. Chemical industry: Used in the production processes of various chemical products, such as dyes, pigments, resins, etc.

2. Pharmaceutical industry: Used for solid-liquid separation in pharmaceutical processes such as traditional Chinese medicine extraction and biological products.

3. Food industry: Used for clarification and separation of foods such as fruit juice, beverages, and seasonings.

4. Metallurgy industry: Used in processes such as metal ore dressing and wastewater treatment.

IV. Maintenance and Upkeep

To ensure the normal operation and extend the service life of the 800-type filter press, the following maintenance and upkeep procedures are required during daily use:

1. Regularly check the condition of the filter cloth and filter plates, and replace them promptly if damaged.

2. Keep the equipment clean to avoid material residue.

3. Regularly check components such as the pressure pump and valves to ensure normal operation.

4. Regularly maintain the equipment and apply anti-rust oil to prevent rust.

In summary, the 800-type filter press features a large filtration area, high degree of automation, and good filtration effect, and is widely used in chemical, pharmaceutical, food, metallurgy, and other fields. Correct use and maintenance methods can ensure the normal operation of the equipment and extend its service life.

Keywords:

Fill in your phone number and E-mail information, and we will contact you within one working day to solve your problems as soon as possible.