Products

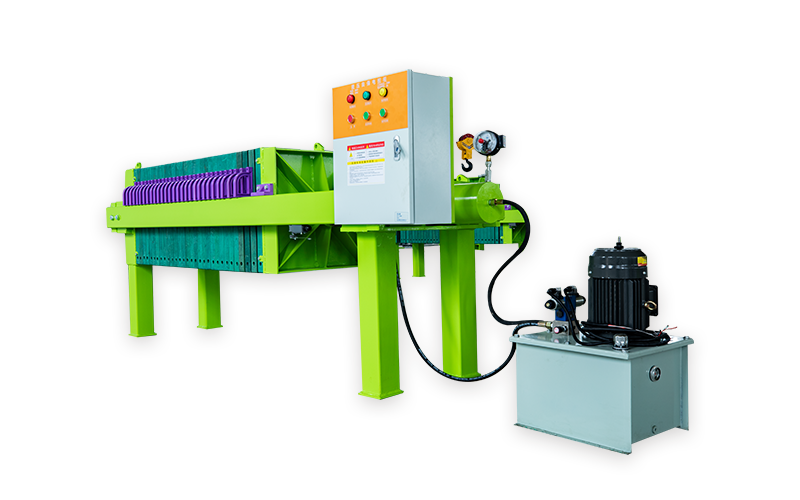

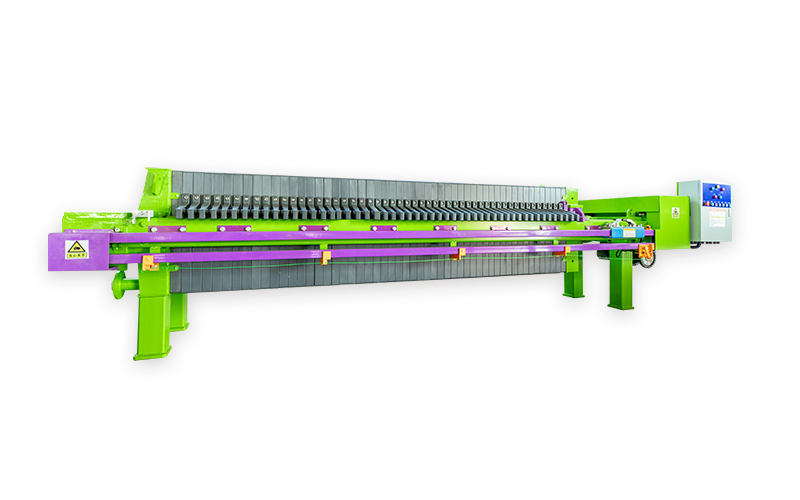

Small filter press equipment

- Product Description

-

I. Introduction to Small Filter Press Equipment

Small filter presses are solid-liquid separation equipment widely used in the chemical, pharmaceutical, food, and environmental protection industries. They are characterized by their compact structure, simple operation, and easy maintenance, making them suitable for solid-liquid separation of various suspensions.

II. Equipment Features

1. Small footprint: Due to optimized design, small filter presses have a small footprint, suitable for locations with limited space.

2. High processing capacity: Despite its small size, it has a high processing capacity and can meet the needs of small and medium-sized production lines.

3. Easy operation: This equipment has a high degree of automation, is easy to operate, and requires no professional training to use.

4. Good filtration effect: Through the pressure filtration process, the separation effect of solids and liquids is good, and the filtrate is clear.

5. Easy maintenance: The equipment has a simple structure and is easy to maintain, reducing maintenance costs.

III. Working Principle

Small filter presses use the principle of pressure filtration for solid-liquid separation. Under the action of pressure difference, the suspension passes through the filter cloth, solid particles are retained on the filter cloth, and the liquid flows out through the filtrate outlet.

IV. Application Fields

1. Chemical industry: Used for solid-liquid separation in the production process of various chemical products.

2. Pharmaceuticals: In the pharmaceutical process, it is used for solid-liquid separation in extraction and concentration processes.

3. Food: Used for filtration in the production of juices, beverages, etc., in the food processing industry.

4. Environmental protection: Used in wastewater treatment, sludge treatment, and other environmental protection projects.

V. Operating Procedures

1. Preparation: Check the integrity of the equipment and prepare the filter medium and the suspension to be filtered.

2. Operation: Start the equipment, pump the suspension to be filtered into the filter press, and start the pressure filtration.

3. Filtration: Under the action of pressure difference, solids and liquids begin to separate.

4. Collection: The liquid is collected through the filtrate outlet, and the solid remains on the filter cloth.

5. Completion: After the filtration is complete, turn off the equipment and perform subsequent processing.

VI. Precautions

1. Check the integrity of the equipment before operation.

2. Keep the equipment clean during operation.

3. Regularly check the filter cloth, filter screen, and other easily damaged parts and replace them in time.

4. Do not touch rotating parts during equipment operation.

In summary, the small filter press is a highly efficient and practical solid-liquid separation equipment widely used in various fields. Its small footprint, simple operation, and high processing capacity make it an ideal choice for small and medium-sized production lines.

Keywords:

Fill in your phone number and E-mail information, and we will contact you within one working day to solve your problems as soon as possible.