Products

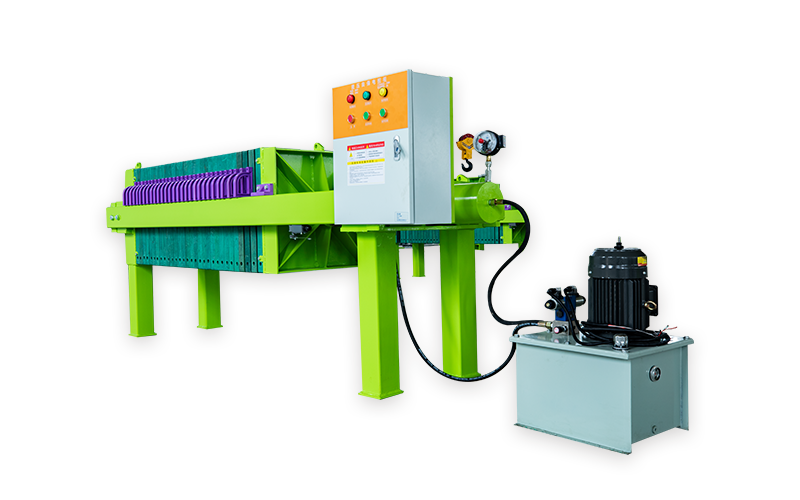

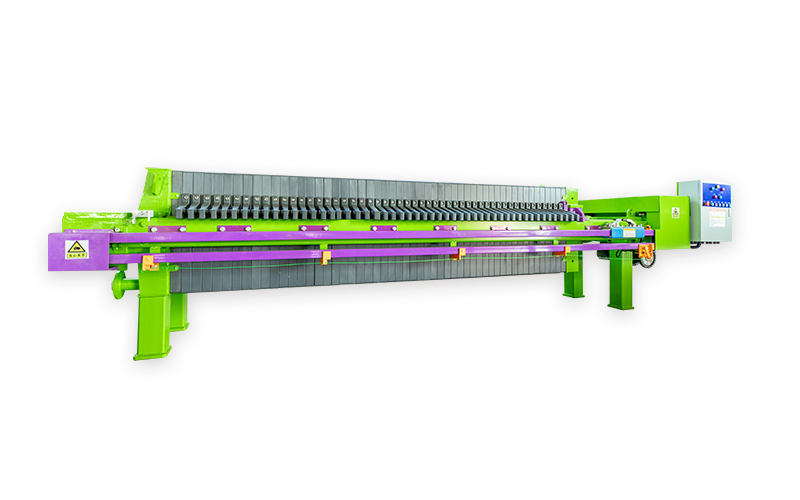

1000 type filter press

- Product Description

-

Filter presses are widely used in various industries, including chemical engineering, pharmaceuticals, food processing, and metallurgy. The 1000-type filter press is a common and popular model on the market. Below, we will detail the features and applications of this equipment.

I. Overview

The 1000-type filter press is a type of large filter press, characterized by its high efficiency and automation. Its main principle is to separate liquids to be filtered through a filter medium using a pressure difference, achieving solid-liquid separation.

II. Main Features

1. High filtration efficiency: Using advanced filtration technology, it can complete the filtration of a large volume of liquid in a short time.

2. High degree of automation: Equipped with an automatic control system, it can realize automatic feeding, automatic pressurization, and automatic unloading, reducing the difficulty of manual operation.

3. Wide range of applications: Suitable for solid-liquid separation of various suspensions, such as in the chemical, pharmaceutical, and food industries.

4. High-pressure resistance: Reasonably designed, it can withstand high working pressure, ensuring filtration effectiveness.

5. Easy operation: The equipment has a compact structure and ample operating space, facilitating daily maintenance.

III. Application Areas

The 1000-type filter press is widely used in the filtration of various chemical reaction liquids in the chemical industry, pharmaceutical liquids in the pharmaceutical industry, and fruit juices in the food industry. In addition, it can also be used in wastewater treatment in the environmental protection industry.

IV. Working Principle

The filter press uses a pump to apply pressure to the liquid to be filtered, causing it to pass through filter cloth or mesh, achieving solid-liquid separation. During filtration, the filter cloth or mesh plays a key role; its quality and selection directly affect the filtration effect.

V. Maintenance

To ensure the normal operation of the filter press and extend its service life, regular inspection and maintenance are required during daily use. This includes checking the condition of the filter cloth or mesh, checking the pressure gauge and valve operation, and cleaning the equipment to maintain internal cleanliness.

In summary, the 1000-type filter press is a highly efficient and automated filtration equipment with a wide range of applications and superior performance. With proper use and maintenance, it can bring long-term benefits to enterprises.

Keywords:

Fill in your phone number and E-mail information, and we will contact you within one working day to solve your problems as soon as possible.