The Unsung Heroes of Industrial Filtration: Filter Plates in Action

Understanding Filter Plates

Have you ever wondered how industries keep their processes clean and efficient? Enter filter plates, the unsung heroes of industrial filtration. These nifty devices are crucial for separating solids from liquids, ensuring that the end product meets quality standards. But don't take my word for it; let's dive into some fascinating industry case studies!

Case Study 1: The Beverage Industry

Picture this: a bustling beverage factory where countless bottles of soda are produced daily. The secret ingredient to maintaining that crisp, clean taste? You guessed it—filter plates. These plates help in clarifying the liquid by removing unwanted particles, ensuring that every sip is as refreshing as the last. Not only do they enhance the taste, but they also extend the shelf life of the product. Talk about a win-win!

Case Study 2: The Pharmaceutical Realm

Now, let's shift gears to the pharmaceutical industry. Here, precision is key. Filter plates play a pivotal role in the production of medicines by ensuring that the active ingredients are free from contaminants. For instance, a major pharmaceutical company adopted a state-of-the-art filtration system using filter plates to refine its production process. The result? A significant reduction in batch failures and an increase in overall efficiency. Who knew something so simple could have such a profound impact?

Case Study 3: Wastewater Treatment

Ever thought about how municipalities clean up wastewater? Enter the world of water treatment facilities! By implementing filter plates, these facilities can effectively remove solids from sewage, turning murky water into a clean resource. It's like magic! With advanced filtration systems, they not only comply with environmental regulations but also contribute to sustainability efforts. Amazing, right?

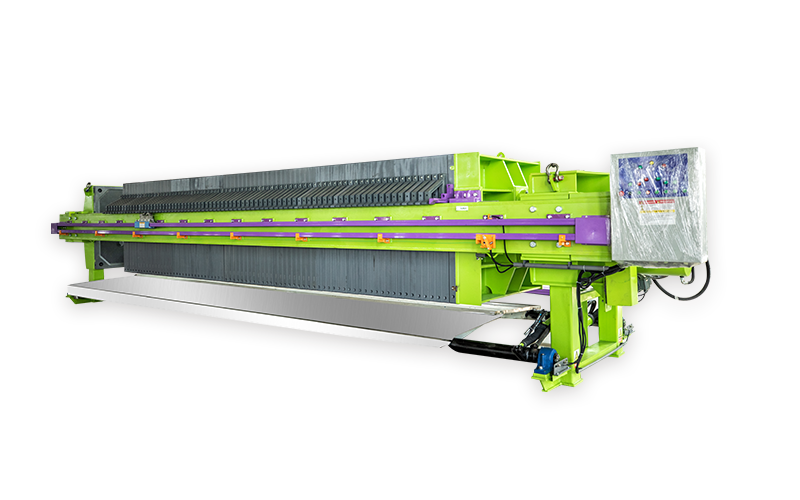

The Technical Side of Filter Plates

So, what makes filter plates so effective? They come in various materials (think polypropylene, stainless steel, and more), each tailored for specific applications. The design typically involves a series of interconnected plates that create a chamber for the liquid to flow through, capturing solid particles along the way. It's this clever engineering that allows industries to maintain high standards while operating efficiently.

Why Filter Plates Matter

In a nutshell, filter plates are not just a piece of equipment; they're a vital component of numerous industries. From beverages to pharmaceuticals and wastewater treatment, these plates ensure that processes run smoothly and products are safe for consumers. Plus, they help companies save money by reducing waste and improving product quality. If that's not a reason to celebrate, I don't know what is!

The Future of Filtration

Looking ahead, the filtration industry is primed for innovation. With the rise of sustainable practices and eco-friendly materials, filter plates are set to evolve. Imagine biodegradable options or smart plates that can self-clean—exciting times ahead!

Final Thoughts

So, next time you enjoy a fizzy drink, take a moment to appreciate the filter plates that made it possible. From ensuring quality to promoting sustainability, these tools are indispensable in countless applications. Here's to the unsung heroes of industrial filtration!