Products

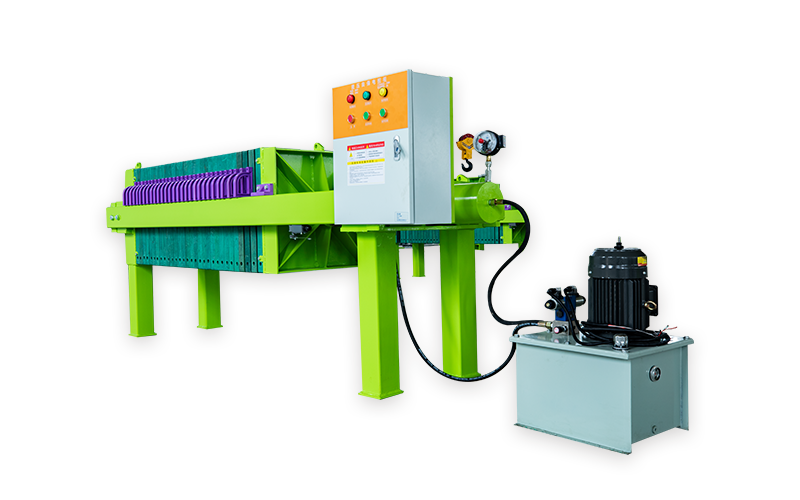

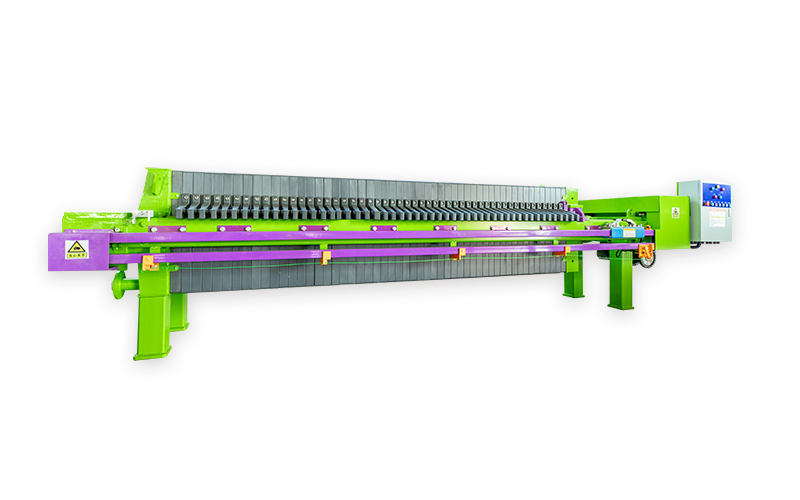

Model 2000 Filter Press

- Product Description

-

The filter press is a solid-liquid separation equipment widely used in chemical, pharmaceutical, food, environmental protection and other fields. Among them, the 2000 type filter press is favored by a large number of users due to its high efficiency and stable performance.

I. Overview

The 2000 type filter press is an efficient, automated filtration equipment mainly used for solid-liquid separation of various suspensions. Its working principle is to drive the liquid through the filtration medium by pressure to achieve solid-liquid separation.

II. Main Features

1. High filtration efficiency: Adopting advanced filtration technology, with fast filtration speed and large processing capacity.

2. High degree of automation: Equipped with an automatic control system, it can realize automatic feeding, automatic filtration, automatic slag discharge and other processes, reducing manual operation intensity.

3. Wide range of application: Suitable for solid-liquid separation of various suspensions, such as in chemical, pharmaceutical, food, environmental protection and other fields.

4. Wear-resistant and corrosion-resistant: Manufactured with high-quality materials to adapt to filtration needs in various corrosive environments.

5. Easy to operate: Humanized design, simple operation, and convenient maintenance.

III. Application Fields

The 2000 type filter press is widely used in chemical, pharmaceutical, food, environmental protection and other fields. In the chemical field, it is mainly used for filtering suspensions generated by various chemical reactions; in the pharmaceutical industry, it is mainly used for filtering medicinal liquids during drug production; in the food industry, it can be used for filtering liquids such as fruit juice and beverages; in the environmental protection field, it can be used for wastewater treatment, etc.

IV. Operation and Maintenance

The operation of the 2000 type filter press is relatively simple; just follow the prescribed operating procedures. For maintenance, regularly inspect and replace the filter media and keep the equipment clean to ensure its normal operation.

V. Precautions

1. Before operation, check whether all parts of the equipment are intact to ensure safety.

2. During operation, follow the prescribed operating procedures to avoid misoperation.

3. In case of any abnormality, stop the machine immediately for inspection, and resume operation after troubleshooting.

In summary, the 2000 type filter press is an efficient, stable, and automated solid-liquid separation equipment widely used in chemical, pharmaceutical, food, and environmental protection fields. During use, simply follow the prescribed operating procedures to ensure normal operation of the equipment and achieve efficient solid-liquid separation.

Keywords:

Fill in your phone number and E-mail information, and we will contact you within one working day to solve your problems as soon as possible.