Unveiling the Power of Filter Plates: A Deep Dive into Their Role

What Are Filter Plates?

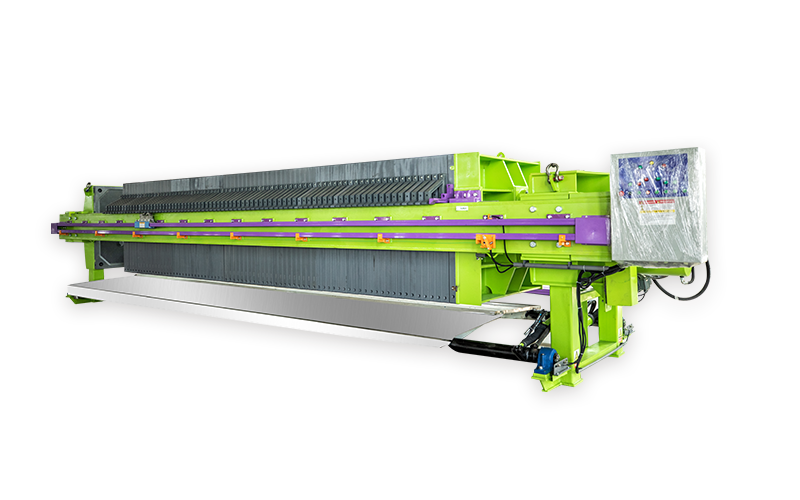

Filter plates are essential components in filtration systems, found in industries ranging from pharmaceuticals to food and beverage. These flat, porous sheets play a pivotal role in separating solid particles from liquids, enabling processes like clarification and concentration. But, how exactly do these seemingly simple devices pack such a hefty punch?

The Anatomy of Filter Plates

At first glance,filter plates might look like ordinary sheets of material. However, they are meticulously designed to facilitate optimal filtration. Made from various materials—such as polypropylene, stainless steel, or even ceramic—these plates are engineered to withstand high pressures and temperatures.

Why Do We Need Them?

Imagine trying to make a perfect cup of coffee without a filter. The result would be a gritty, murky mess! Likewise, in industrial processes,filter plates ensure that the final product is pure and free from unwanted particles. They are crucial in maintaining quality control and efficiency.

Applications of Filter Plates

From water treatment to chemical processing,filter plates have a wealth of applications. Here are a few standout uses:

- Pharmaceuticals: In this industry,filter plates help purify raw materials and ensure that end products are safe for consumption.

- Food and Beverage: Filtration is key in beer brewing and juice production, where clarity and taste can make or break a product.

- Oil and Gas: Here,filter plates are used to separate impurities from crude oil, ensuring that the refining process runs smoothly.

How They Work

So, how dofilter plates do their magic? It's all about the size and structure of the pores in the material. Larger particles get trapped while smaller ones pass through, leading to cleaner, clearer liquids. Think of it as a bouncer at a club—only the right crowd gets in!

Choosing the Right Filter Plates

When it comes to selecting the rightfilter plates, several factors come into play:

- Material: Depending on the application, different materials may be more suitable. For instance, stainless steel is durable and resistant to corrosion, making it ideal for harsh environments.

- Pore Size: The right pore size can significantly impact efficiency. Smaller pores trap more particles but may slow down the process.

- Compatibility: Ensure that the filter plate material is compatible with the fluids being processed to avoid any unwanted reactions.

Maintenance Matters

Just like a car needs regular check-ups,filter plates require maintenance to function optimally. Regular cleaning and inspection can prolong their lifespan and ensure they perform effectively. Neglecting this can lead to decreased efficiency and potentially costly downtime!

The Future of Filter Plates

The filtration industry is ever-evolving, andfilter plates are no exception. With advancements in material science and technology, we can expect to see more efficient and durable options hitting the market. Innovations like smart filtration systems that monitor performance in real-time are on the horizon, makingfilter plates even more indispensable.

Conclusion

In summary,filter plates may seem like a small cog in the vast machinery of industrial processes, but their impact is anything but minor. From enhancing product quality to driving efficiency, these unsung heroes deserve a spotlight. So, whether you're in the trenches of manufacturing or simply enjoy a good cup of coffee, remember:filter plates are here working hard behind the scenes!