Products

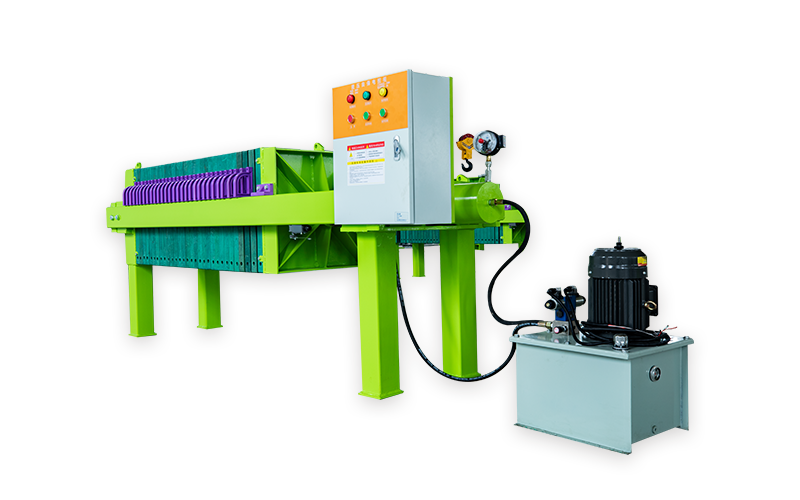

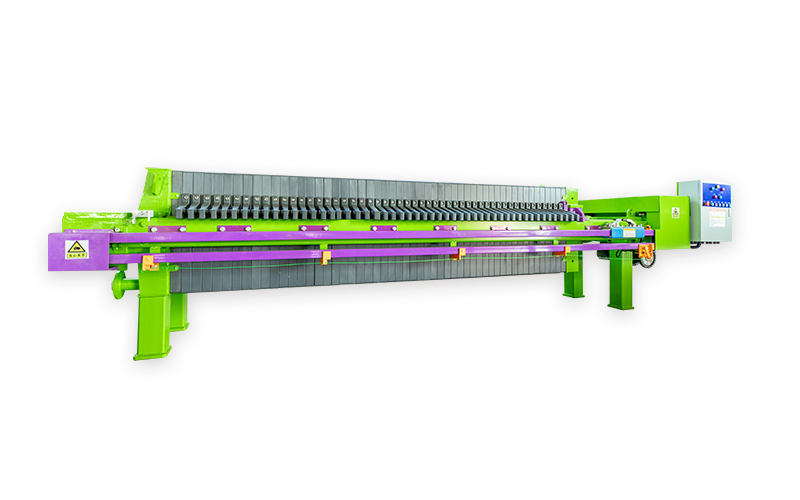

Large filter press equipment

- Product Description

-

Large filter presses are crucial equipment in modern industrial fields, especially in the chemical, pharmaceutical, food processing, and mineral processing industries. These machines have complex designs and structures, with high-efficiency filtration capabilities to meet the needs of large-scale production.

I. Overview of Large Filter Press Equipment

A large filter press is a highly efficient solid-liquid separation device that uses pressure to drive fluids through a filter, achieving solid-liquid separation. Its design handles large volumes of fluid and is suitable for industrial production environments requiring continuous, large-scale filtration operations.

II. Main Features

1. High-efficiency filtration: Large filter presses have extremely high filtration efficiency and can quickly process large volumes of fluid.

2. Automated operation: Modern large filter press equipment is equipped with an advanced automated control system, allowing for one-button operation and reducing manual intervention.

3. High durability: Manufactured using high-strength materials, suitable for harsh working environments.

4. Flexible and versatile: Different filtration methods and filter plates can be selected according to different production needs.

III. Application Areas

Large filter presses are widely used in the chemical, pharmaceutical, food processing, and mineral processing industries. In the chemical industry, they are used to process mixtures produced by various chemical reactions; in the pharmaceutical industry, they are used to extract and purify drug components; in food processing, they are used to filter juices and other liquid foods; and in mineral processing, they are used to extract metals from ores.

IV. Technical Parameters and Performance Indicators

The technical parameters and performance indicators of large filter presses vary depending on the brand and model. Main parameters include processing capacity, filtration area, and working pressure. Performance indicators include filtration efficiency, filtrate clarity, and operational stability.

V. Operation and Maintenance

The operation of large filter presses is relatively simple; one-button operation can be achieved through the automated control system. However, regular maintenance is key to ensuring the equipment's normal operation. This includes cleaning the equipment, inspecting the filter plates, and replacing damaged filter cloths.

VI. Market Trends and Development

With the continuous development of the industrial field, large filter press equipment is also constantly improving. Future trends include a higher degree of automation, greater durability, higher filtration efficiency, and more flexible operation.

In general, large filter press equipment is an indispensable part of modern industrial fields, and its efficient and stable performance provides strong support for industrial production.

Keywords:

Fill in your phone number and E-mail information, and we will contact you within one working day to solve your problems as soon as possible.