Filter Press: An Efficient Separation Tool Empowering Industrial Production

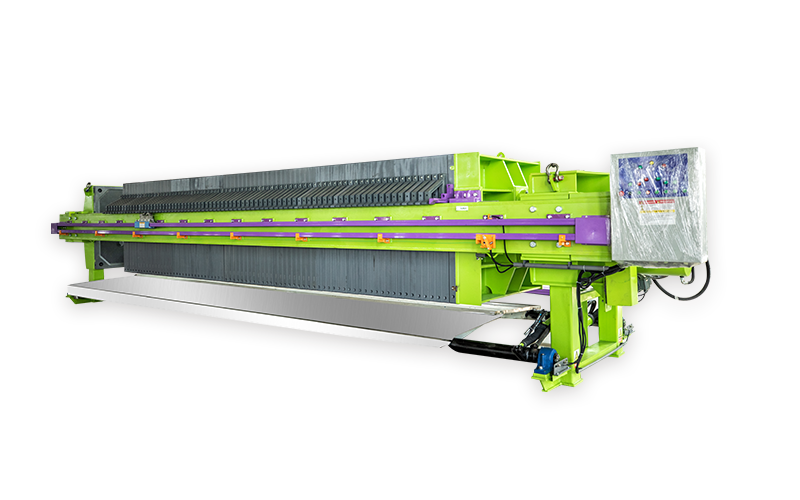

In the modern industrial system, the filter press, as a core equipment for solid-liquid separation, has become an indispensable key device in chemical industry, mining, municipal sewage, food processing and other fields due to its excellent separation efficiency and stable operation performance. By applying a certain pressure, it allows the liquid in the suspension to pass through the filter cloth, while the solid particles are intercepted to form filter cakes, thus achieving rapid solid-liquid separation and effectively improving the purity and efficiency of material processing.

With technological iteration, filter presses have been upgraded from traditional models to intelligent and large-scale ones. The integration of functions such as automatic plate pulling, intelligent filter cake thickness monitoring and remote control not only reduces labor costs, but also ensures the stability and consistency of processing effects through precise control of filtration parameters. Meanwhile, the research and development of acid and alkali resistant, high-strength filter plate materials have further expanded its application range under complex working conditions.

In the current era where the concept of green development is deeply rooted in people's minds, the role of filter presses in environmental protection fields such as resource recovery and sewage purification has become increasingly prominent, helping enterprises achieve the goal of "reducing pollution and carbon emissions". Choosing filter press equipment that meets production needs is an important measure to improve production efficiency and practice sustainable development.