Unlocking Efficiency in Industry: The Power of Filter Plates

Introduction to Filter Plates

Ever heard offilter plates? If not, you're in for a treat! These nifty components play a pivotal role in various industries, from food processing to pharmaceuticals. So, what's the buzz about?

What Are Filter Plates?

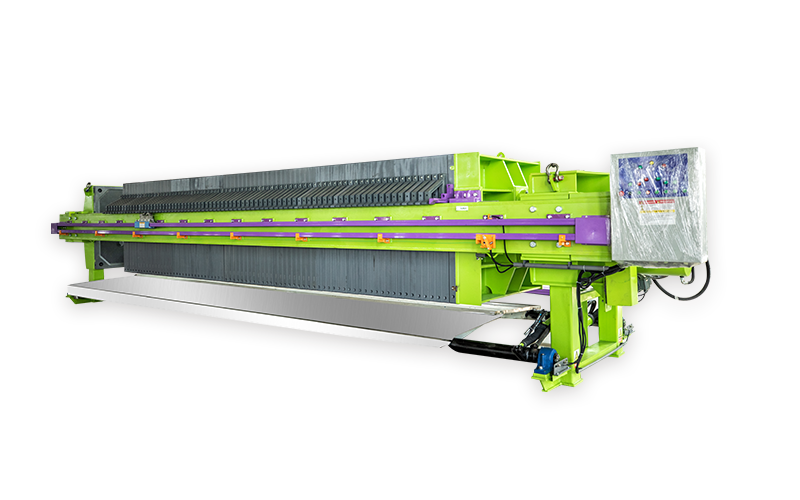

Simply put,filter plates are flat or slightly curved structures designed to separate solids from liquids or gases. They come in various shapes and sizes, but they all share a common goal: to enhance efficiency in filtration processes. Think of them as the unsung heroes of industrial operations!

Why Use Filter Plates?

Ah, the million-dollar question! The benefits of usingfilter plates can't be overstated. For starters, they offer:

- Efficiency: By optimizing the filtration process,filter plates can significantly reduce processing time.

- Cost Savings: Less time and fewer resources spent on filtration mean more money in your pocket.

- Quality Control: They help maintain consistent product quality by ensuring that unwanted particles are effectively removed.

Types of Filter Plates

Now that we're on the same page about whatfilter plates are, let's dive into the various types available. Each type serves unique purposes, catering to different industrial needs:

1. Membrane Filter Plates

These bad boys are designed for high-performance filtration. They feature a special membrane that enhances the separation process, making them ideal for applications requiring ultra-fine filtration.

2. Standard Filter Plates

These are your all-rounders! Standardfilter plates are versatile and can be used in various settings. They are commonly employed in food and beverage industries.

3. Recessed Filter Plates

If you're dealing with thick slurries, recessedfilter plates are your best bet. They're designed to hold more material, allowing for longer filtration cycles without constant changeovers.

Applications of Filter Plates

From the chemical industry to wastewater treatment,filter plates are everywhere! Let's break it down:

1. Food and Beverage Industry

In this sector,filter plates ensure that everything from fruit juices to beer is crystal clear and free from impurities. Cheers to that!

2. Pharmaceutical Industry

Here, quality is king! Filter plates help maintain stringent cleanliness standards, ensuring that medications are safe and effective.

3. Water Treatment

With increasing concerns over water quality,filter plates play a crucial role in removing contaminants, making our water safe to drink.

Best Practices for Using Filter Plates

Alright, you've got the basics down, but how can you maximize the performance offilter plates? Here are some tips:

- Regular Maintenance: Keep those plates clean! Regular maintenance ensures optimal performance and longevity.

- Choose the Right Type: Understanding your specific needs will help you select the best filter plate for your application.

- Monitor Performance: Keep an eye on filtration rates and quality to ensure everything is running smoothly.

Conclusion

In the grand scheme of industrial processes,filter plates are essential players that can't be overlooked. They offer efficiency, cost savings, and consistent quality. So, whether you're in the food industry or pharmaceuticals, consider integratingfilter plates into your processes and watch your productivity soar!