Unlocking Efficiency: The Lowdown on Filter Plates

What Are Filter Plates?

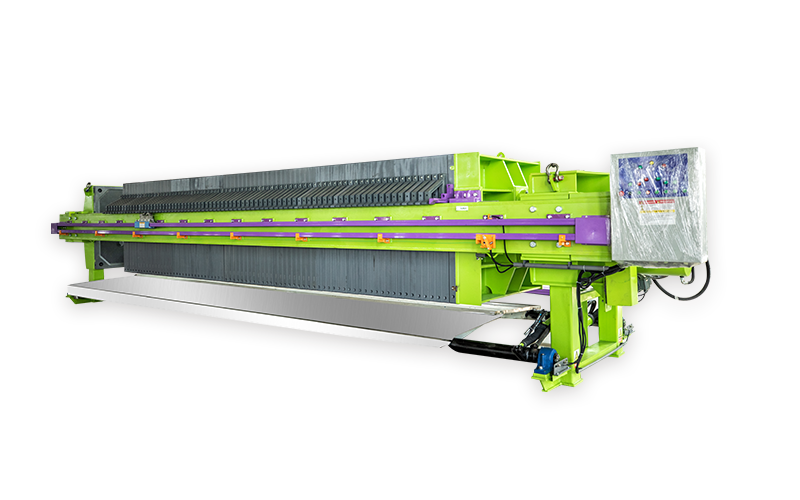

Ever heard offilter plates? If you haven't, you're in for a treat! These nifty devices play a pivotal role in the filtration process across various industries. Simply put,filter plates are specialized tools used to separate solids from liquids, making them an essential component in manufacturing, food processing, and even chemical industries!

The Anatomy of Filter Plates

So, what's the deal with thesefilter plates? Well, they come in different sizes and shapes, tailored to meet specific needs. Typically made from durable materials like polypropylene or stainless steel, they feature a series of openings or membranes designed to trap particles while allowing fluids to pass through. Can you say efficient?

Why Use Filter Plates?

Now, you might wonder, why not just use a regular filter? Aha! Great question! Filter plates are particularly beneficial for large-scale operations where the volume of materials is significant. They offer a higher throughput, meaning they can handle more material in less time. Plus, they're often easier to clean and maintain, which is a huge win in any production environment.

Applications of Filter Plates

You might be surprised to learn how versatilefilter plates can be. Here's a quick rundown of where you might find them:

- Food and Beverage Industry: From juice production to wine filtration,filter plates ensure clarity and purity in consumables.

- Chemical Manufacturing: They aid in the separation of valuable chemicals from solvents, enhancing recovery rates.

- Pharmaceuticals: In the production of medicines,filter plates help to maintain stringent quality standards.

The Benefits of Filter Plates

Let's break it down. Here are some key benefits of usingfilter plates:

- Efficiency: They significantly reduce the time and labor involved in filtration processes.

- Cost-Effective: By optimizing operations, they help cut down on costs in the long run.

- Consistency: Filter plates provide uniform results, ensuring product quality is never compromised.

Choosing the Right Filter Plate

Okay, so you're sold onfilter plates. But how do you choose the right one? Well, it boils down to understanding your specific needs. Consider the following:

- Material: Depending on your application, you may need a specific type of material.

- Size and Shape: Make sure it fits your existing equipment!

- Pore Size: This affects the filtration efficiency, so choose wisely.

Maintenance Matters

Just like any other equipment,filter plates require proper maintenance. Regular cleaning and inspections can prolong their lifespan and ensure optimal performance. It's a small price to pay for long-term efficiency!

Conclusion: Filter Plates - A Must-Have!

To wrap it up,filter plates are more than just industrial tools; they're the backbone of efficient filtration processes across multiple sectors. Whether you're in food processing, pharmaceuticals, or chemical manufacturing, embracing these devices can lead to remarkable improvements in productivity and product quality. So, why not consider integratingfilter plates into your operations? You won't regret it!