Filter Press: The Unsung Hero of Industrial Efficiency

Introduction: A Deep Dive into Filter Presses

Ever heard of a filter press? If not, don't sweat it! It's one of those unsung heroes in the industrial world that often flies under the radar. But let me tell you, it's a game changer! In this article, we'll explore how filter presses are making waves across various industries, boosting efficiency, and contributing to sustainability. Buckle up because we're diving into the nitty-gritty!

What is a Filter Press?

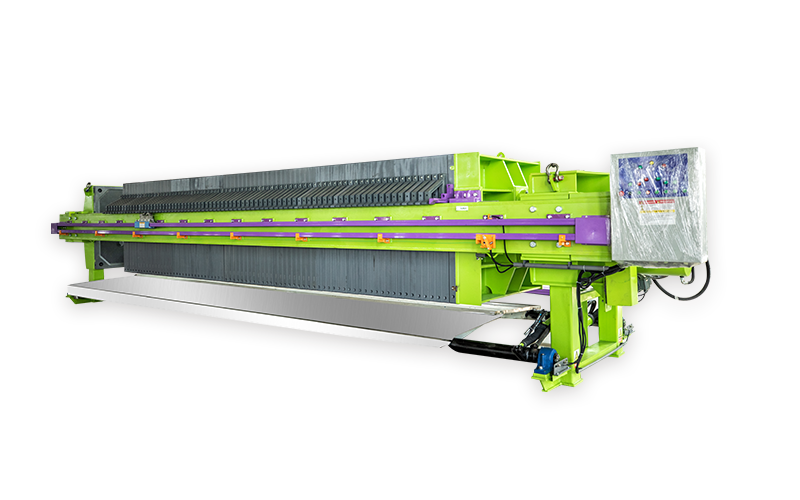

Alright, let's break it down. A filter press is a piece of equipment used for solid-liquid separation. It's got plates, frames, and a hydraulic system that work together to squeeze out liquid from slurry (think muddy water). This process results in dry cake (solid waste) and clarified liquid (filtrate) ready for disposal or further treatment. Sounds simple, right? But the impact is anything but!

Why Industries Rely on Filter Presses

Here's the scoop: industries are constantly on the lookout for ways to enhance productivity while minimizing waste. Enter the filter press. This nifty device can handle large volumes of slurry, which makes it a favorite for sectors like mining, food and beverage, and wastewater treatment.

In mining, for example, it helps separate valuable minerals from unwanted materials. In food processing, it's essential for clarifying juice or oil. And in wastewater treatment, it plays a crucial role in recycling water and reducing environmental impact. Talk about multi-tasking!

Efficiency at Its Best

Now, let's get technical for a hot second. A filter press operates in batches, which means it can be turned on and off as needed. This not only saves energy but also allows for precise control over the filtration process. Isn't that neat? Plus, the resulting dry cake is often easier and cheaper to dispose of than wet sludge. Double win!

Sustainability Matters

In today's world, sustainability is the name of the game. Companies are under pressure (pun intended!) to reduce their carbon footprint and improve waste management. The use of a filter press aligns perfectly with these goals. By facilitating water recycling and minimizing waste, it helps industries operate in an eco-friendly manner. Who wouldn't want to be a part of that movement?

On the Horizon: Innovations in Filter Press Technology

So, what's next for filter presses? With advancements in technology, we're seeing innovations that enhance their efficiency and effectiveness. For instance, automated filter presses are on the rise, allowing for continuous operation with less human intervention. This not only boosts productivity but also reduces labor costs. Talk about a win-win situation!

Moreover, smart technology is being integrated into filter presses, enabling real-time monitoring and data collection. This means better performance tracking and maintenance, which can save companies a bundle in the long run. If you think of it, filter presses are not just keeping up with the times; they're setting the pace!

Challenges Ahead

Of course, it's not all sunshine and rainbows. The initial investment for a filter press can be hefty, and some companies might hesitate to make that leap. Additionally, proper maintenance is crucial to ensure optimal operation. But hey, as they say, you've got to spend money to make money!

Conclusion: The Future is Bright

To wrap things up, filter presses are an integral part of modern industrial processes. They not only enhance efficiency but also contribute to sustainable practices that are becoming increasingly important in today's world. So, the next time you hear someone mention a filter press, you'll know it's not just a piece of machinery; it's a vital component in the quest for a cleaner, greener future. Cheers to that!