Demystifying the Filter Press: Your Go-To Guide for Common Queries

Understanding the Filter Press

When it comes to separating solids from liquids, the filter press is a star player in industrial processes. But what is it, and why does it matter? Let's dive into the nitty-gritty!

What Exactly is a Filter Press?

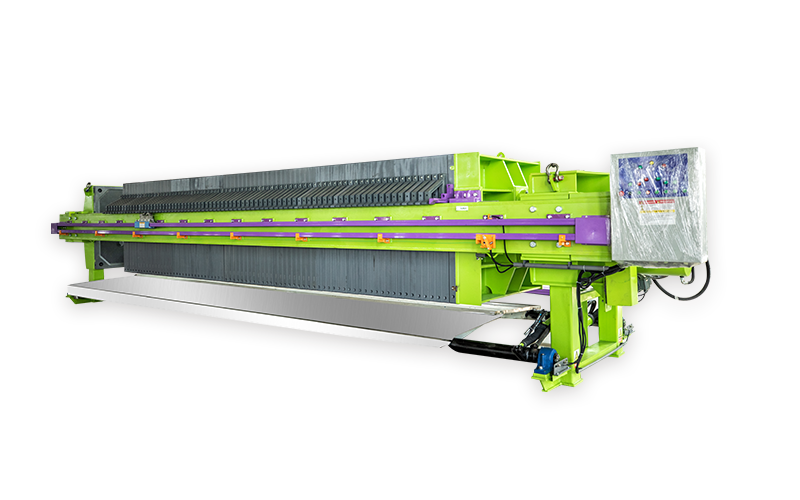

In simple terms, a filter press is a type of equipment used to separate liquids and solids. Picture this: you've got a mixture of mud and water, and you want that clean water back. Enter the filter press! It uses pressure to push the liquid through a membrane, leaving the solid behind. This bad boy is commonly found in industries ranging from pharmaceuticals to wastewater treatment.

Common Questions About Filter Presses

Now, let's tackle some frequently asked questions. Trust me, these will come in handy!

1. How does a Filter Press work?

Ah, the magic of mechanics! A filter press works by utilizing a series of plates and frames. The process starts when slurry (that's the mix of solids and liquids) is pumped into the press. The plates are then pushed together, creating a chamber. As pressure builds, the liquid is forced out through the filter cloth, leaving the solids behind. Voila! You've got clean liquid on one side and a cake of solids on the other.

2. What materials can a Filter Press handle?

Great question! Filter presses can handle a variety of materials. You can expect them to process everything from sludge to ores to food products. However, not all filter presses are created equal, so it's essential to choose one suitable for your specific material.

3. How often should I clean my Filter Press?

Now, here's where maintenance comes into play. Ideally, you should clean your filter press after every batch. Regular cleaning helps maintain efficiency and extends the lifespan of your equipment. If you let the solids build up, you'll end up with a clogged mess, and nobody wants that!

Troubleshooting Your Filter Press

So, what happens when things go south? Here are some common issues and quick fixes!

1. Low Cake Formation

If you notice that the solid cake is thinner than usual, it might be due to improper pressure settings or incorrect filter cloth selection. Double-check those settings and switch out the cloth if necessary.

2. Leakage

Uh-oh! If you spot leakage around the edges, it's likely that the plates aren't sealing properly. Make sure they're tightly fitted and inspect for any wear and tear. A little maintenance goes a long way!

3. Slow Filtration Rate

Feeling stuck? A slow filtration rate can be caused by clogged filter cloths or too much solid content in the slurry. Clean those cloths and evaluate your material input to get back on track.

Final Thoughts on Filter Presses

In conclusion, the filter press is an indispensable tool in many industries. By understanding how it works and addressing common issues, you can optimize its performance and prolong its life. So, whether you're a newbie or a seasoned pro, keep these tips in your back pocket. Happy filtering!