Unveiling the Magic: How a Filter Press Works

What's the Buzz About Filter Presses?

Ever found yourself wondering how industries manage to separate liquids from solids? Well, you ain't alone! The answer lies in the nifty contraption known as the filter press. This machine is a game-changer, especially in the world of wastewater treatment, mining, and food processing. But what's the real deal behind its operation? Let's dive in!

The Basics: How Does a Filter Press Work?

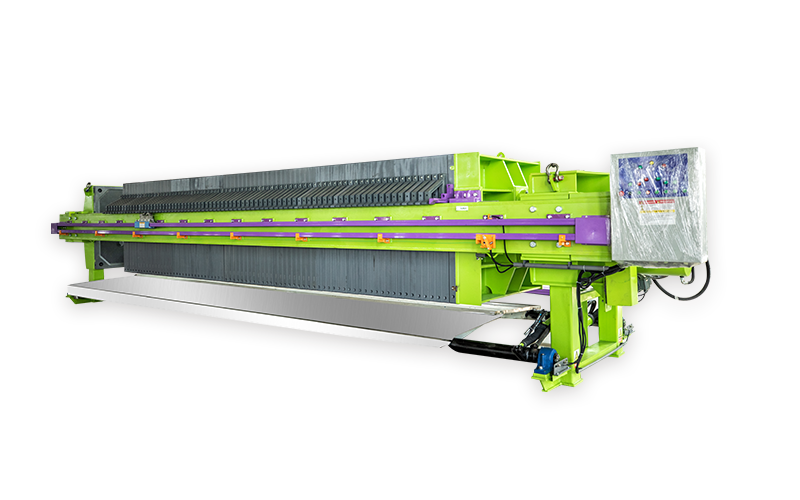

At its core, a filter press functions on a pretty straightforward principle, yet it's packed with intricate details. Picture this: you have a series of plates and frames, and when you pump a slurry into it, magic happens! The liquid gets squeezed out, leaving behind a solid cake. Sounds simple, right? But there's more to the story.

Step-by-Step Breakdown

- 1. Slurry Preparation: Before anything, the slurry (a mixture of solid and liquid) needs to be prepared to ensure optimal filtration.

- 2. Filling the Press: The slurry is pumped into the filter press, filling the chambers created by the plates.

- 3. Filtration: As the pressure builds, the liquid starts to pass through the filter cloth, leaving the solids behind.

- 4. Cake Formation: Over time, the solids accumulate, forming a cake that can be easily removed.

- 5. Discharge: Finally, the filter press is opened, and the solid cake is discharged, ready for further processing or disposal.

Applications Galore!

So, where do we see these filter presses in action? Well, you name it! From the culinary arts to heavy-duty mining operations, they're everywhere. Here's a quick rundown:

- Food Industry: Think olive oil extraction or juice clarification.

- Chemical Manufacturing: Perfect for separating solids from liquids in chemical processes.

- Wastewater Treatment: An essential tool for dewatering sludge.

- Mining: Used to recover metals and minerals from ore.

Why Go for a Filter Press?

Now, you might be asking yourself, 'What's the big deal about using a filter press?' Let's break it down:

- Efficiency: They're designed to maximize filtration and minimize waste.

- Cost-Effective: Reduces the volume of waste that needs to be disposed of.

- High Quality: Produces high-quality solids and liquids.

- Versatility: Adaptable to various industries and processes.

Common Misconceptions

There's a lot of chatter out there about filter presses, and not all of it is accurate. Here are a couple of common myths:

- Myth 1: They're only for large operations. Not true! They come in various sizes, suitable for small businesses too.

- Myth 2: They're complicated to operate. False! With the right training, anyone can master it.

Final Thoughts

In a nutshell, a filter press is like the unsung hero of many industries. Its ability to efficiently separate solids from liquids makes it invaluable. Whether you're in food processing, mining, or wastewater treatment, understanding its workings can give you an edge. So, the next time you come across a filter press, you can appreciate the science behind it—because it's more than just machinery; it's a crucial part of our industrial world!