Unlocking Efficiency: The Power of Filter Press in Industrial Solutions

Introduction: The Unsung Hero of Industry

Ever been knee-deep in a project where the end product seems just out of reach? Well, that’s where the filter press steps in like a knight in shining armor! This nifty piece of equipment is a game-changer in various sectors, streamlining processes and ensuring that operations run smoothly. So, let's dive into the fascinating world of filter presses and explore their impact on industrial solutions!

What is a Filter Press?

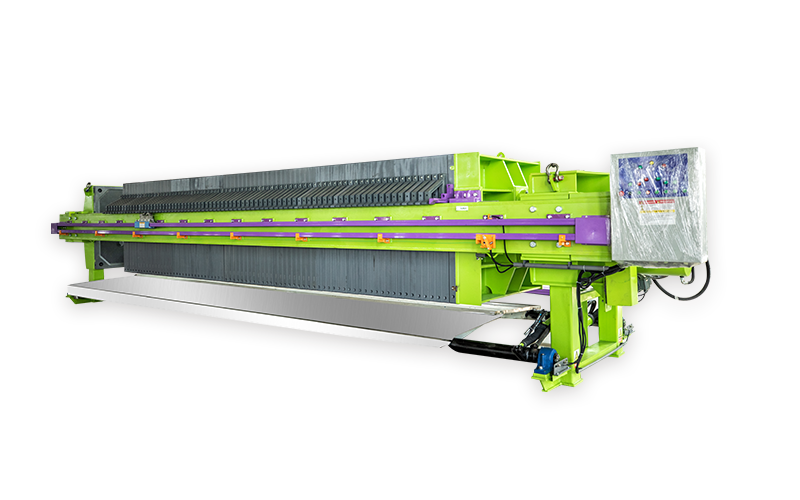

At its core, a filter press is a solid-liquid separation device. It operates by using pressure to force liquids through a filtering medium, allowing the solids to be trapped in a cake. This mechanism is pretty nifty, right? It’s widely used in industries such as mining, food processing, and wastewater treatment, to name a few.

Why You Should Care

Now, you might be wondering, “Why should I care about a filter press?” Well, the truth is, efficiency is the name of the game in any industry. With a filter press, companies can save time, reduce waste, and improve their bottom line. It’s the unsung hero that makes sure everything runs like a well-oiled machine!

The Mechanics Behind the Magic

Let’s get a tad technical for a second! A filter press consists of a series of frames and plates that form chambers. When the slurry (that’s the mixture of solids and liquids) is pumped into the press, it fills these chambers. Then, hydraulic pressure is applied, and voilà! The liquid is squeezed out, leaving behind a solid cake.

Isn’t that pretty cool? The solids can then be disposed of or reused, while the liquid is often treated further. This clever arrangement not only maximizes yield but also minimizes environmental impact. Talk about a win-win!

Applications Across Industries

Hold onto your hats, folks! The versatility of filter presses is astonishing. Here are a few industries where they truly shine:

- Mining and Minerals: From separating valuable minerals to managing tailings, filter presses are crucial.

- Food and Beverage: They help clarify juices, oils, and other liquids, ensuring product quality.

- Wastewater Treatment: Filter presses are instrumental in dewatering sludge, making disposal easier.

- Chemicals: In chemical processing, they assist in recovering valuable materials and enhancing purity.

Benefits Galore

Alright, let’s break it down! Here are some of the benefits of employing a filter press in your operations:

- Cost-Effective: By reducing waste and improving recovery rates, businesses can see significant savings.

- High Efficiency: Filter presses work swiftly, meaning less downtime and more productivity.

- Environmental Impact: With better waste management, companies can meet regulatory standards and enhance their sustainability efforts.

- Versatility: As mentioned earlier, they’re suitable for a wide range of applications!

Choosing the Right Filter Press

With so many options out there, how do you pick the right filter press for your needs? Here are some pointers:

- Understand Your Needs: Assess the type of material you will be filtering and the desired output.

- Size Matters: Ensure the filter press can handle the volume you require.

- Maintenance: Look for models that are easy to maintain and have readily available parts.

- Cost vs. Benefit: Don’t just go for the cheapest option; consider long-term benefits too.

Conclusion: The Future is Bright

In the grand scheme of things, filter presses are paving the way for more efficient industrial solutions. Whether you’re in the mining sector or managing a wastewater treatment plant, these devices are essential. So, if you’re looking to enhance your operations, it might be time to consider investing in a filter press. Cheers to a cleaner, more efficient future!

Next: