Unlocking Efficiency: The Marvel of Filter Press Technology

What is a Filter Press?

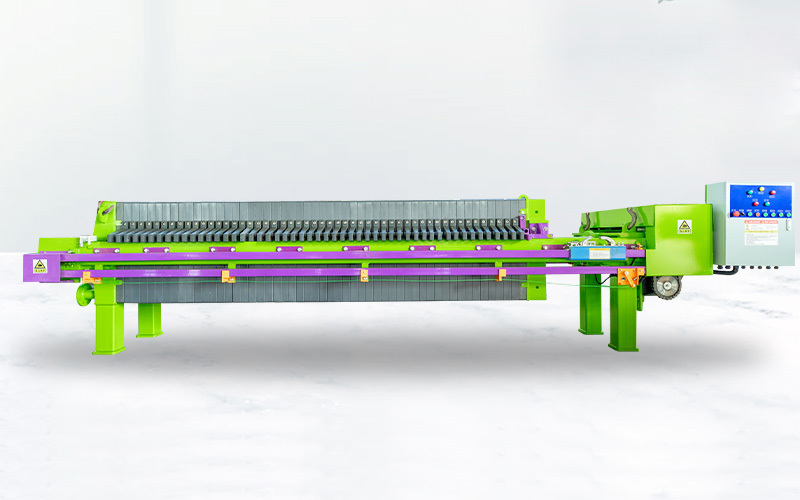

Ah, the filter press! A nifty piece of machinery that plays a crucial role in the world of filtration and separation. At its core, it’s designed to separate solids from liquids, making it a game-changer in industries ranging from mining to wastewater treatment. But how does it work, you ask? Let’s dive in!

How Does a Filter Press Work?

Picture this: a series of plates stacked together, creating chambers that hold the slurry (a mixture of solid and liquid). When the slurry is pumped into the filter press, pressure is applied, forcing the liquid to escape while leaving the solids behind. Voilà! You’ve got yourself a cake of solids and clarified liquid. This process is not only efficient but also environmentally friendly, as it minimizes waste.

Why Choose a Filter Press?

Now, you might be wondering, why should I opt for a filter press over other filtration methods? Well, let me lay it out for you:

- High Efficiency: Filter presses are known for their high solid-liquid separation efficiency, making them a top choice for many.

- Cost-Effective: While the initial investment might seem hefty, the long-term savings on waste disposal and operational costs are significant.

- Versatile Applications: Whether you’re in the food industry, chemical manufacturing, or mineral processing, a filter press can be tailored to fit your needs.

Types of Filter Presses

Believe it or not, there’s more than one flavor of filter press! Let’s break down a few:

- Plate and Frame Filter Press: The classic design, perfect for various applications.

- Membrane Filter Press: Uses a flexible membrane to increase the cake dryness, reducing drying time and costs.

- Automatic Filter Press: For those who prefer a hands-off approach, this type automates the filtration process, saving time and labor.

The Advantages of Using a Filter Press

Let’s get real for a second—adopting new technology can be daunting. But the benefits of using a filter press are hard to ignore:

- Reduced Environmental Impact: By efficiently separating solids from liquids, filter presses contribute to less waste and lower emissions.

- Improved Product Quality: Consistent filtration leads to higher quality products, which is always a win.

- Easy Maintenance: Most filter presses are designed for easy cleaning and maintenance, meaning less downtime.

The Future of Filter Press Technology

As industries evolve, so does technology. The future of filter press systems looks bright, with advancements in automation, energy efficiency, and material innovation on the horizon. Imagine a world where filter presses not only save time and money but also contribute to a greener planet!

In Conclusion

So there you have it! The filter press isn’t just a piece of equipment; it’s a pivotal part of many industrial processes. By understanding its workings and benefits, you can make a more informed decision about its place in your operations. Whether you’re looking to enhance efficiency, reduce waste, or improve product quality, a filter press might just be the solution you’ve been searching for. Don’t hesitate to explore this fantastic technology further!

Previous: