Understanding the Filter Press: A Deep Dive into Its Functionality and Uses

What is a Filter Press?

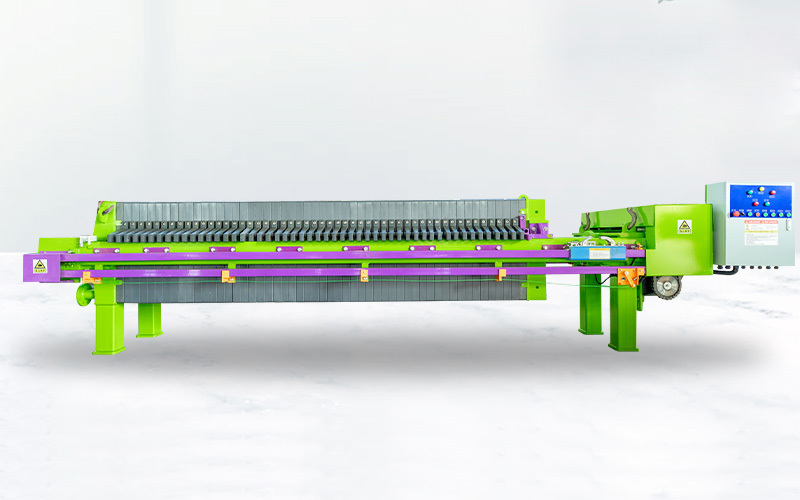

Ever wondered how industries manage to separate liquids from solids efficiently? Well, let me introduce you to the unsung hero of separation processes: the Filter Press. This nifty piece of equipment is a staple in various sectors, from mining to food processing, and it works wonders in dewatering sludges and liquids.

The Mechanics Behind the Magic

Now, you might be scratching your head, thinking, "How does this thing even work?" Let’s break it down! In simple terms, a filter press consists of a series of plates and frames that hold filter cloths. When a slurry is pumped into the press, the solids are trapped in the filter cloths while the liquid drains away. This process can be likened to squeezing out water from a sponge—only more industrial and a tad more complicated!

Step-by-Step Breakdown

- Filling: The slurry is pumped into the filter press.

- Filtration: The liquid (filtrate) passes through, while solids remain trapped.

- Cake Formation: As more solids accumulate, a cake forms.

- Pressing: Extra pressure may be applied to maximize solid capture.

- Discharge: The filter cakes are removed, and the process can start anew.

Why Use a Filter Press?

Alright, let’s get real. Why should industries invest in a filter press? The advantages are plentiful! First off, it’s effective at maximizing solid recovery and minimizing waste. Plus, it’s versatile enough to handle a wide range of materials. From wastewater treatment to mineral processing, it’s got you covered. And let’s not forget—this equipment is relatively easy to maintain!

Applications Galore

There’s no shortage of industries that rely on the filter press. It’s like the Swiss Army knife of filtration! Here are just a few sectors where this device shines:

- Mining: Used for separating minerals and dewatering tailings.

- Food and Beverage: Essential for juice and wine clarification.

- Pulp and Paper: Helps in recovering fibers and reducing waste.

- Chemicals: Supports the separation of various chemical products.

A Few Fun Facts

Did you know that the concept of the filter press dates back to the 19th century? It's true! Back then, it was a simple cloth stretched over a frame. Fast forward to today, and we have automated models that can handle massive volumes with ease. Talk about progress!

The Environmental Impact

In today's eco-conscious world, the filter press plays a pivotal role in waste management and environmental sustainability. By efficiently separating solids from liquids, it reduces the amount of waste sent to landfills and helps purify wastewater. It’s a win-win for both industries and Mother Earth!

In Conclusion

So, there you have it! The filter press is more than just a piece of machinery; it’s a vital player in many industrial processes. With its ability to efficiently separate solids from liquids, it helps businesses save costs, minimize waste, and contribute to a cleaner environment. If you ever find yourself in a factory or processing plant, take a moment to appreciate the hard work that a filter press does behind the scenes!

Next time you come across one, give it a nod—it's doing its part to keep the world spinning!

Previous:

Next: